The Bielefeld specialist for industrial process heat, heat transfer and energy conversion heat 11 (Germany) has successfully passed an extensive quality audit of the Stuttgart company COPERION.

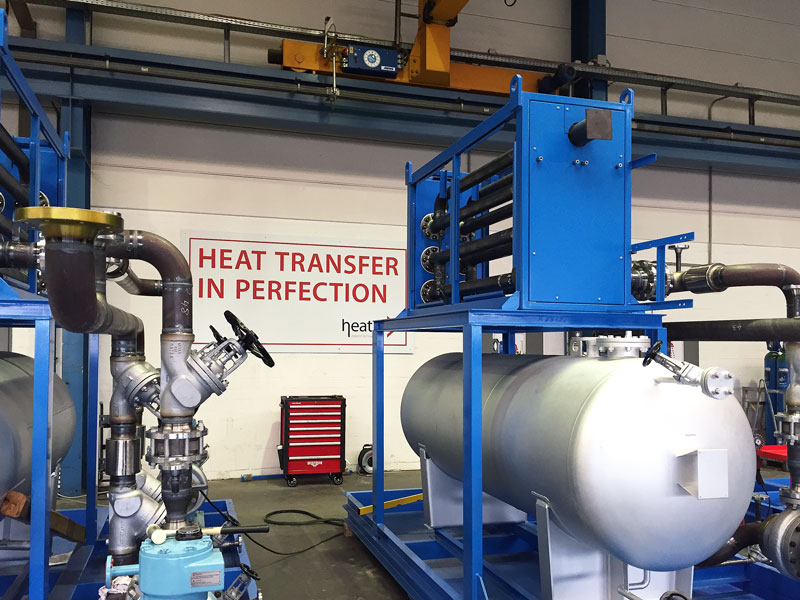

Since the beginning of 2011 on the market, heat 11 completed an audit of the important customer COPERION from Stuttgart (Germany) at the beginning of this year. COPERION produces extruders for the manufacture of PE and PP that are used around the world. The plants supplied by heat 11 (thermal oil electric heater and heating-cooling units) serve the heating of the so called die plate of the extruder and the temperature control of the gear pump.

In the last week, COPERION carried out an audit on the internal operational procedures (project management, procurement processes, work preparation, etc.) and the consistent implementation of the production standards set by COPERION at heat 11 was successfully tested.

heat 11 – with the new production location in Loehne (Germany) – was assessed as a very secure and clean company working under high quality standards and providing good working conditions to its employees. Upon successful completion of the certification audit Dr. Dietmar Hunold, managing partner of heat 11, received the congratulations of the QM department.

»This success is another milestone of our consequent quality policy«. Hunold was very pleased with the result. heat 11 is very confident to be able to perfom important new projects with COPERION in 2017. »The foundation for this was laid now.« concluded Hunold.

QUALITY MANUFACTURE

Comments are closed.